High quality

standards

Our working methods and equipment meet the most demanding standards in the sector and are recognised and approved by our customers.

Our certifications and labels

ISO 13485 & ISO 22716 certifications

Being certified ISO 22716 and ISO 13485, Euro Wipes offers the guarantee of high-quality production free of any risks for the user, with each manufacturing step perfectly controlled and subject to strict verifications. Our objective: to increase the safety of our products for consumers.

ISO 13485 certification

It is recognised by players in the medical devices’ sector. It is an internationally recognised standard. ISO 13485 is an independent standard that is similar to ISO 9001, especially concerning the Process approach. It also imposes the setting up of Risk Management (ISO 14971), traceability, sterilisation, sealing qualifications, validation and qualification of process equipment and its long-term monitoring.

ISO 22716 certification

It provides guidelines relating to Good Manufacturing Practices (GMP) for cosmetics and takes account of this sector’s specific needs. ISO 22716 is composed of a series of practical and organisational elements concerning the management of human factors, as well as technical and administrative factors on aspects relating to the product’s quality and safety. All of EURO WIPES staff are trained in Good Manufacturing Practices

Whatever the type of products made, Euro Wipes scrupulously follows these Good Manufacturing Practices (GMF) which define the quality standards and provide the guidelines for the production, packaging, verification, storage and shipping of products.

COSMOS certification by Ecocert Greenlife

COSMOS certification by Ecocert Greenlife means compliance with procedures relating to packaging, quality, origin and traceability specifications.

The guarantees of this certification are :

- GM-free products without any petrochemical ingredients (with the exception of authorised preservatives): parabens, phenoxyethanol, perfumes and artificial colours

- Compliance with environmental protection measures (selective sorting, waste water treatment, ban on the use of aggressive cleaning products, etc.)

- Non-polluting transformation and manufacturing procedures throughout the production process

- Label verifications to ensure that they clearly mention the percentage of ingredients of natural origin and organic ingredients.

A COSMOS ORGANIC certified cosmetic or care treatment implies that:

- 100% of the raw materials comply with COSMOS guidelines

- A minimum of 95% of the total ingredients are of natural origin

- A minimum of 20% of the total ingredients come from Organic Farming

A COSMOS ORGANIC certified cosmetic or care treatment implies that:

- 100% of the raw materials comply with COSMOS guidelines

- A minimum of 95% of the total ingredients are of natural origin

FSC label

FSC (Forest Stewardship Council) is a label guaranteeing that the production of a wood-based product complies with sustainable forest management specifications.

Euro Wipes uses non-woven material made with wood pulp from FSC certified sustainably managed forests.

Nordic Ecolabel

The Nordic Ecolabel, also known as Nordic Swan, or more simply The Swan, is an official label common to Scandinavian countries for environmentally-friendly products and services.

It is a general ecological label that takes account of all of a product’s environmental impacts throughout its life cycle, from the extraction of the raw materials, through to its recycling. Very strict, this label is also one of the best-known ecolabels in the world.

Bra Miljöval eco-label

The Bra Miljöval (Good Environmental Choice) eco-label is a Swedish label for nature conservation. It analyses the product’s life cycle and complies with very strict specifications concerning respect for the environment and human health.

This label is certified in Sweden but it can also be found in Denmark, Finland and Norway.

The Allergy quality label

The Allergy quality label is awarded to products designed for people suffering from allergies and intolerances following a strict and regulated certification process by inspection (technical commission, medical council) and auditing bodies.

This label is managed by Service Allergie Suisse but is internationally recognised.

IFS

IFS means International Featured Standards. IFS HPC (or DPH) are common guidelines that apply to companies which process home care, perfume and hygiene products and aim to ensure that the products do not represent any dangers for consumers’ safety. The audit includes more than 220 requirements divided up into 5 chapters: Management Responsibilities. Management System; Resource Management; Manufacturing process: Measurements, analyses, corrective actions, incident management.

We are certified IFS HPS Scope 1 and 2 High Level: 1 audit per year.

If you want to find out more about sub-contracting cosmetics and why it is best to opt for a certified sub-contractor, I recommend you read the article on our blog devoted to this subject:

Manufacturing process:

-

Receipt

& verification -

Production

of the lotion -

Impregnation

and packaging -

Storage

and shipping

1. Receipt & verification

All the packaging articles and chemical raw ingredients are strictly verified according to an internal sampling plan or following the customer’s requirements.

Documents with different specific verification criteria are drawn up by material typology and a microbiological analysis is also carried out on all chemicals and on Non-Woven natural fibre products.

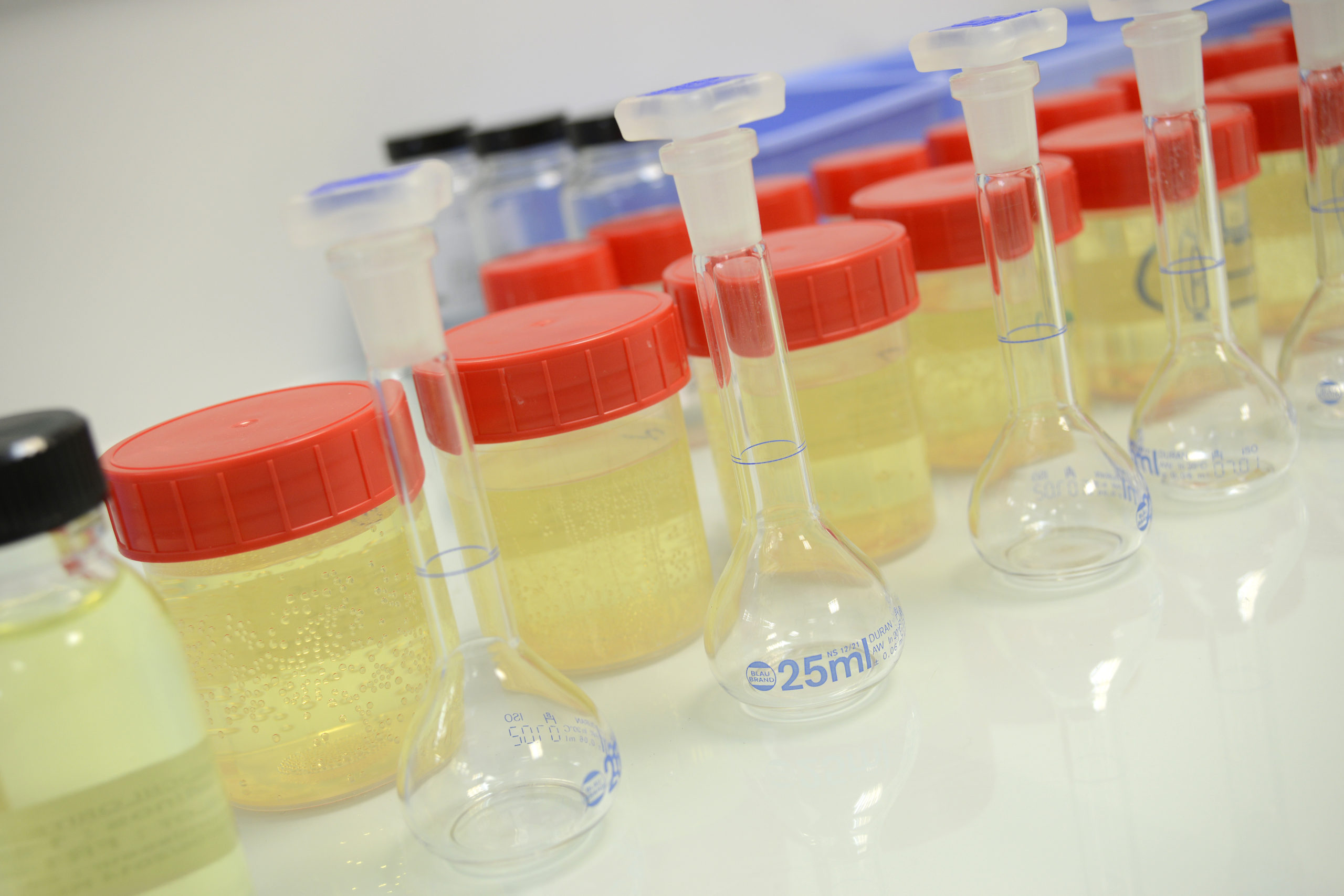

2. Production of the lotion

The chemicals are firstly weighted in dedicated areas (Detergence or Cosmetic) to comply with Good Manufacturing Practices (ISO 22716). The operations are carried out and recorded at our weighing station which communicates directly with SAGE X3 (systematic and recorded traceability, deducted from stock, etc.)

The raw ingredients are first mixed together in a preparation tank to produce a pre-mixture, and then transferred to a storage tank where it is completed and diluted with our main raw ingredient, European Pharmacopoeia quality reverse-osmosis water. Checks are carried out on pH, Density, refraction index, etc. after the lotion has been produced.

3. Impregnation and packaging

Once the line has been connected for lotions, the launch of the process is authorised by Quality Control if all the criteria for the first products manufactured on the line are conform. The line is started if, and only if, the first products are conform to requirements.

Next, we verify different criteria, including mass. Complete verification of the weight of the impregnated piles using very precise scales that check the weight daily and which is inspected every year by a specialist service-provider.

Auto-monitoring is carried out every half hour at specific points (codification, opening, appearance, impermeability) by the production teams, as well as on critical check points in our risk management (ISO 14971) and, at the same time, quality checks on random samples from the line are also performed on the basis of all the criteria to be verified (impermeability, weight, opening, dimensions, etc.). All the Quality checks will be reviewed when drawing up the batch record and are an integral part of the elements required for the release of the batches.

4. Storage and shipping

All of our products from the production lines are stored systematically in our Finished Products warehouse under Q status (pending Quality Control release). Only our QC Manager and Quality Director are authorised to release (or not) the Finished Products on the basis of the release results (pH, microbiological analyses, sometimes dosing of preservatives) before shipping. Standard or specific batch records based on customer’s requirements are then sent to the customer.

Process Supply Chain:

-

Customer

order -

Receipt and verification

of materials -

Production

-

Storage

-

Customer

delivery

1. Customer order

- Validation of volume forecasts

- Component orders

2. Receipt and verification of materials

- Raw materials

- Packaging articles

3. Production

- Lotion production

- Packaging

4. Storage

- Storage of finished products in the warehouse

- Verifications and release of batches

5. Customer delivery

Thank you for your interests in our products

To access the products sheets please fill in the following information :